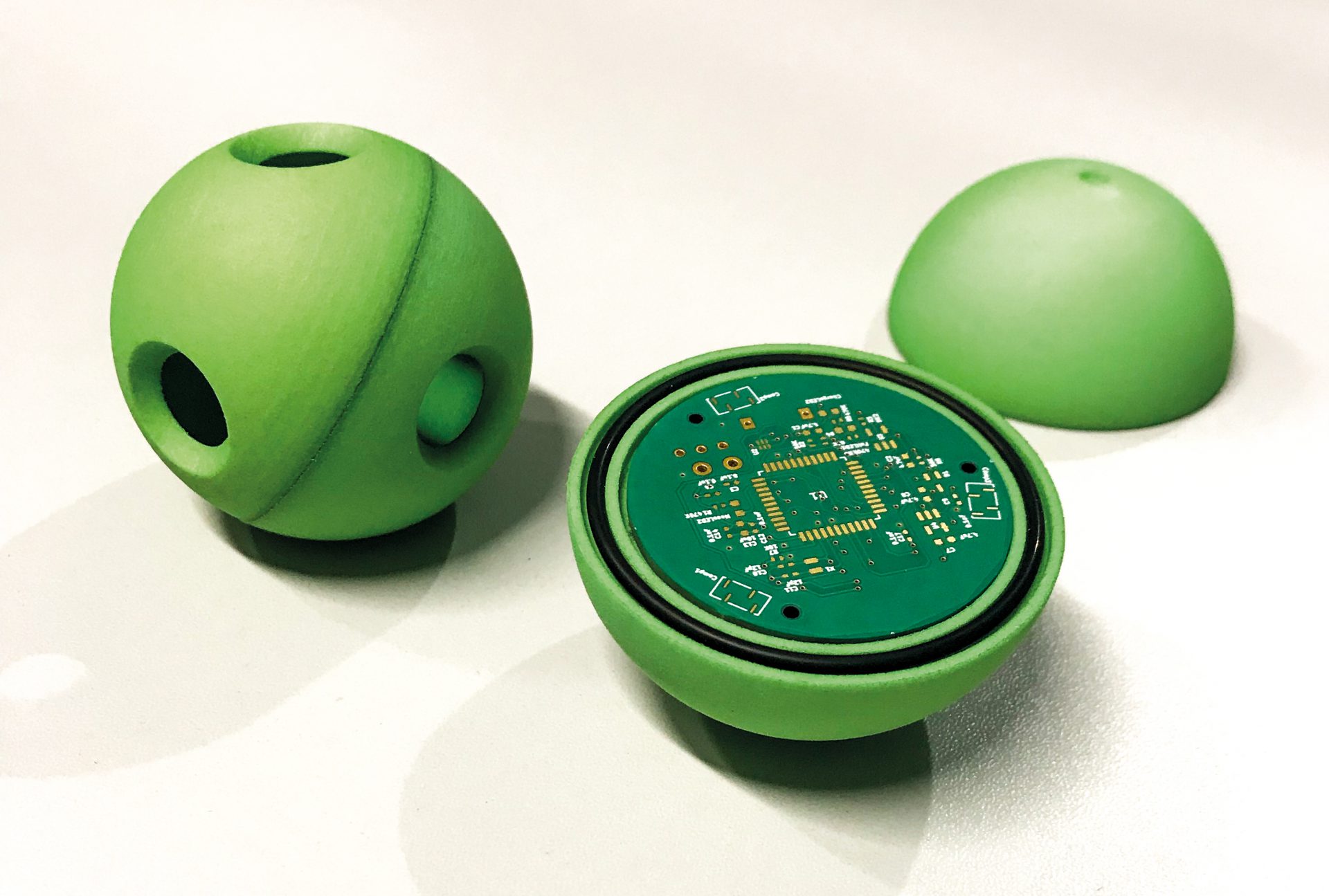

Both cases would benefit from enhanced inspection methods and the floats from the Phoenix project are already making their way to these systems. Within Smarble we want to show that these inspections can benefit from more technologies from Phoenix. Phoenix floats are inserted in operational pipe and tanks and measure their own interal movement. After extraction, this data is analyzed and the results can be used for extracting information about both the process and the environment through which the motes move. The floats move have no propulsion or steering and thus essentially operate while the system is in normal operation.

In the Phoenix project two additional technologies have been developed, ultrasound measurement for both ranging between motes and to walls, and, based on the ultrasound measurements, and modelling of the environment. In Smarble we want to create and show the business case for bringing these technologies to market. Through two pilots and market analyses we want to assess the technology, its economic and societal potential.